Yale Big Forklifts Salt Lake City

Frame

To be able to handle the lifting stresses of standard forklift, the frame has to consider these extremely important factors. Yale frames offer optimal strength and rigidity for a long life. They provide maximum protection to all truck parts.

Each and every part of a Yale frame has undergone computer application testing and major laboratory testing in order to achieve the highest level of durability to be able to meet and surpass their customer's needs.

Unitized Design

The design of the units offer welded steel construction for internal component protection and better rigidity. Overall these frames provide for an exceptionally strong product. This design makes the lift truck a strong and powerful equipment.

Finite Element Analysis

The finite element analysis is used for testing and designed for amazing durability and strength. Using the best materials available helps to make the best products in the long run.

Motors

In order to add productive value, industrial grade lift trucks need to be tough for use in industrial applications. The machines must function at demanding performance levels, usually in harsh environments. They should be able to work at maximum uptime. Additionally, these machinery preferably must depend on minimal cost to operate.

Yale lift trucks are built and designed with Industrial Grade Critical Components, providing exceptional productive value and economic life. These are the differences customers have come to rely on.

The electric motors ensure that the lift truck lifts and travels at the required speed for maximum throughput and productivity. AC Motors really lessen maintenance costs as they work without brushes. The motors are insulated with Class H insulation for better heat resistance. Moreover, steering motor functionality is integrated into the hydraulic motor that increases dependability and simplifies the system.

- Clark Warehouse Forklifts Salt Lake City

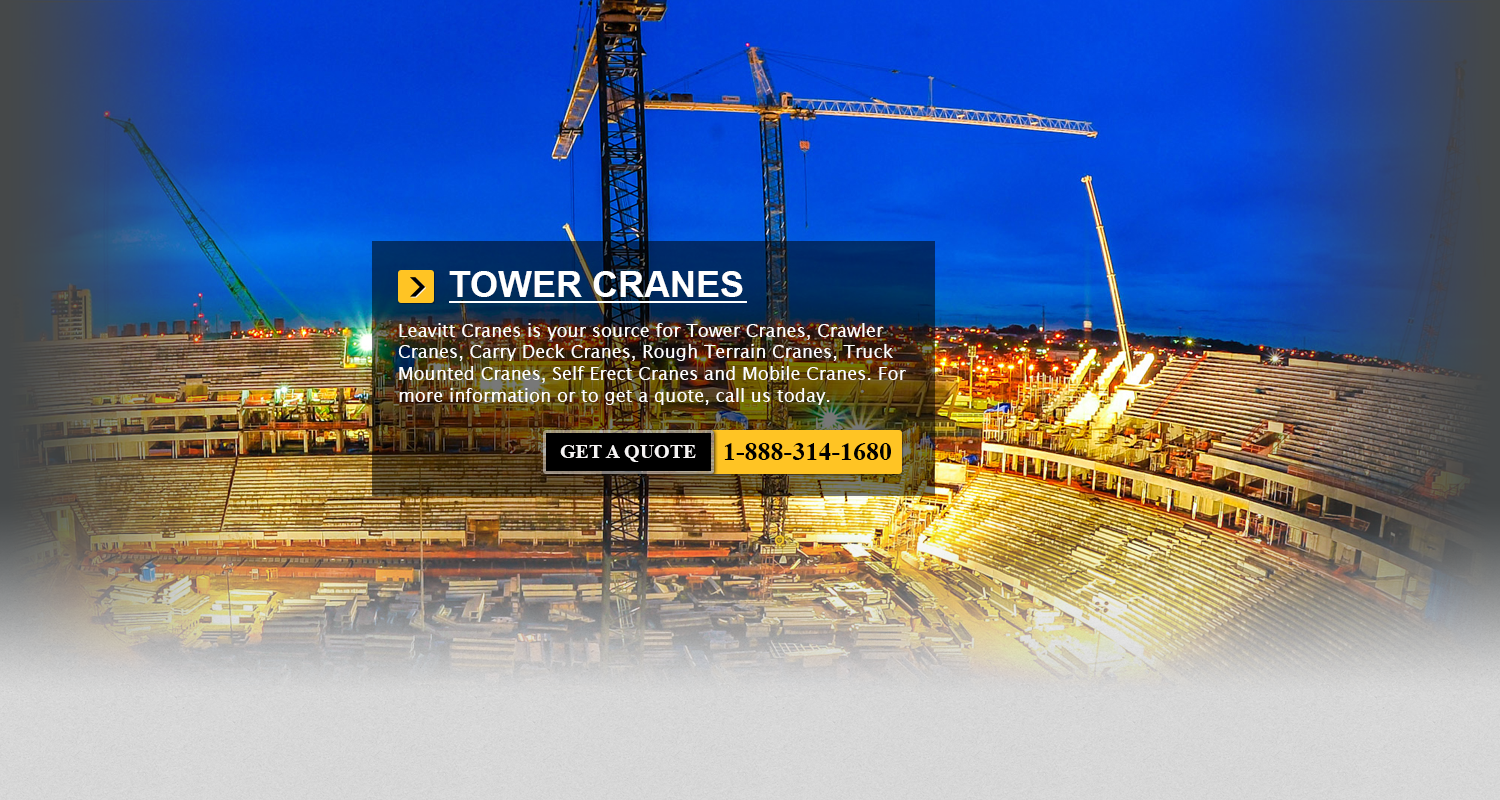

Forklift Safety Rules and Tips Each and every year, there are roughly 20,000 cases of accidents that are connected to using forklifts in the United States alone. And each and every year about 100 deaths... More - Liebherr Construction Cranes Salt Lake City

During the year 1949, the Liebherr family business was established by Hans Liebherr. His first claim to fame was the success of his affordable and easy-to-assemble mobile tower crane. It was upon this creation that... More - Haulotte Electric Boom Lifts Salt Lake City

The electric boom aerial lift allows personnel to carry out maintenance and building work at heights which were not previously accessible. An electric boom is designed with a work platform which can be lifted to... More - Jungheinrich Cushion Tire Forklift Salt Lake City

Pneumatic Tires The majority of tires utilized in modern times are considered to be pneumatic tires. The use of rubber in tires enabled the creation of pneumatic tires which allowed for a much more comfortable... More - Yale Propane Forklifts Salt Lake City

Narrow aisle lift trucks work by increasing the ratio of the storage space to the width of the aisle. Yale features the double reach NDR and the single reach NR units for aisle widths of... More