Jungheinrich Dual Fuel Forklift Salt Lake City

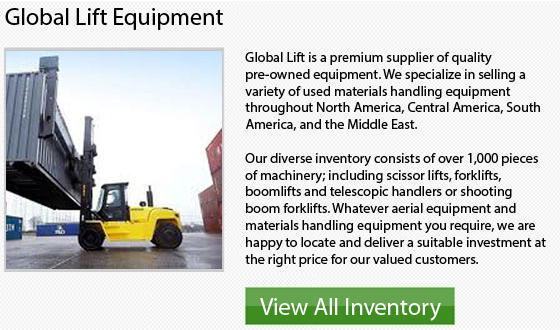

Vital machinery used on construction locations consist of vehicles like the lift truck, the bulldozer and the bobcat. Forklifts could vary from extremely big to somewhat small models. These kinds of equipment are designed to raise cargo and move supplies and goods inside retail or warehouse settings. A lot are made to easily maneuver in tight, narrow areas. It takes both training and ability to correctly use a lift truck.

Lift trucks could be found in most warehouses as they are vital pieces of equipment for effective materials handling. They are usually utilized in warehouses and stockrooms to retrieve and place huge or heavy objects which are stored up high. These types of equipment are important for productivity in work environments where there is a small place to store a huge range of stock. These trucks are manufactured to transport huge pallets around in warehouses.

Forklift operators in North America are required by law to undergo a training and certification course. This training could be done on the jobsite or in a schoolroom or lecture style setting. Normally training is delivered at the workplace. Training and accreditation usually means a raise for the person obtaining new skills. Forklifts have standard operating measures, that makes it easy to get taught on different types of forklifts.

The cab on smaller lift trucks support only one worker who could move the machinery inside small areas. The bigger machines are huge and can lift cars, trucks or other kinds of of machinery. Forklifts could easily raise thousands of pounds.

Construction companies usually give salary raises to workers who undergo the training. Employers will normally send an employee to classes to train on a huge piece of machinery. Willingness to train on a bull dozer, a forklift or a bobcat will pay off.

- Clark Counterbalance Forklifts Salt Lake City

The forklift is a material handling equipment utilized to raise and transport loads from one location to another. Each forklift part has a particular function. Various parts can be used to transport the load either... More - Liebherr Construction Cranes Salt Lake City

During the year 1949, the Liebherr family business was established by Hans Liebherr. His first claim to fame was the success of his affordable and easy-to-assemble mobile tower crane. It was upon this creation that... More - Haulotte Electric Boom Lifts Salt Lake City

The electric boom aerial lift allows personnel to carry out maintenance and building work at heights which were not previously accessible. An electric boom is designed with a work platform which can be lifted to... More - Jungheinrich Cushion Tire Forklift Salt Lake City

Pneumatic Tires The majority of tires utilized in modern times are considered to be pneumatic tires. The use of rubber in tires enabled the creation of pneumatic tires which allowed for a much more comfortable... More - Yale Propane Forklifts Salt Lake City

Narrow aisle lift trucks work by increasing the ratio of the storage space to the width of the aisle. Yale features the double reach NDR and the single reach NR units for aisle widths of... More